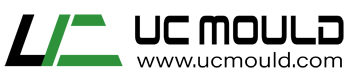

Preform mold, professional mold development and design, injection mold, blowing mold, mold manufacturing and production, PET preform mold, professional and efficient, quality-oriented, welcome to quote consultation!

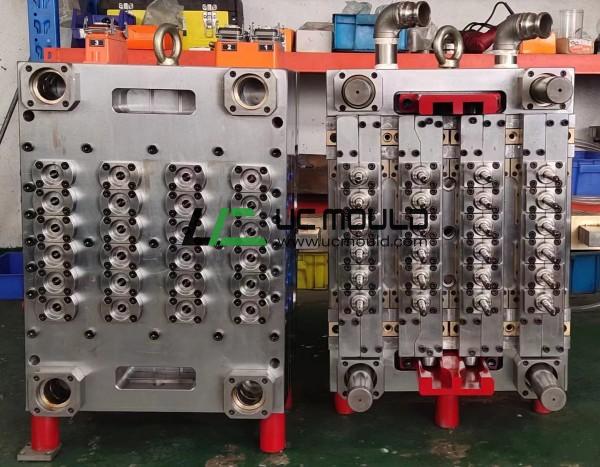

After years of careful research, we have developed a set of independent self-locking structure preform molds. The needle valve structure preform molds have been widely used in many packaging industries such as edible oil, beverages, candy, cosmetics, pesticides, and medicine. The characteristics of high quality, high efficiency, energy saving and long service life are sold well at home and abroad, and are praised by the majority of users. They are exported to the United States, Europe, South America, the Middle East, Southeast Asia, Africa and other countries and regions.

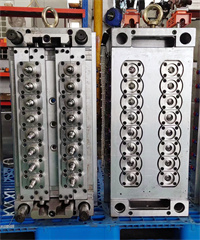

We have advanced mold processing equipment and strong technical force. We fully use CAD/CAE/CAM system to design, shape and program various preform molds, and have the ability to manufacture high, precise and sharp molds. In design, we use CAD, 2D & 3D software to design to meet the needs of various shapes of plastic products in today's market.

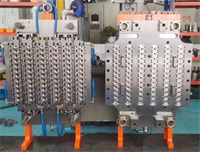

The technical advantages of the preform hot runner system:

1. Reduce the loss and cost of raw materials;

2. Reduce the recycling, sorting, crushing, drying and storage of waste, which can reduce the number of crushers, save labor, reduce energy consumption, and save the required production site;

3. Avoid the influence of the use of recycled materials on reducing the quality of the parts;

4. Ensure the consistency of injection molded parts and improve the accuracy of plastic parts;

5. Increase the injection volume of the part and improve the compressibility of the plastic melt;

6. Strengthen the injection function and improve the injection molding process;

7. Reduce the required injection and holding time;

8. Reduce the required clamping force;

9. Shorten the mold opening stroke in the injection operation cycle and eliminate the time it takes to take out the nozzle material;

10. Shorten the injection cycle and strengthen automation to improve production efficiency.

The embodiment of the key performance elements of the hot runner system:

1. Precisely control the temperature of melt plastic to eliminate material degradation;

2. Balanced runner design, evenly filling the part cavity;

3. The appropriate size of the hot nozzle ensures the smooth flow of the melt and the full filling of the cavity;

4. Correct gate structure and size to ensure that the cavity is fully filled and the needle valve gate is closed in time. Thereby reducing casting and shortening the injection molding cycle;

5. There is no dead angle area in the flow channel to ensure fast color change and prevent material degradation;

6. Minimize pressure loss;

7. The pressure holding time is reasonable.