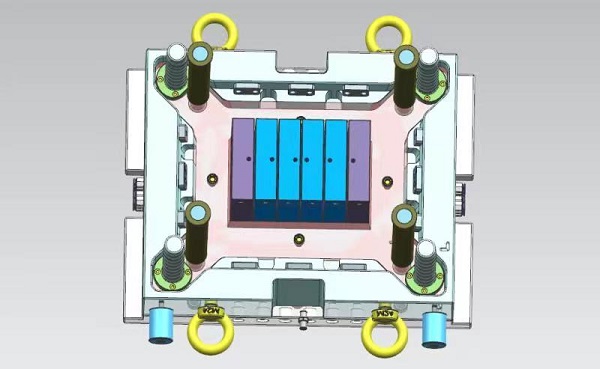

Battery box moulds keypoints :

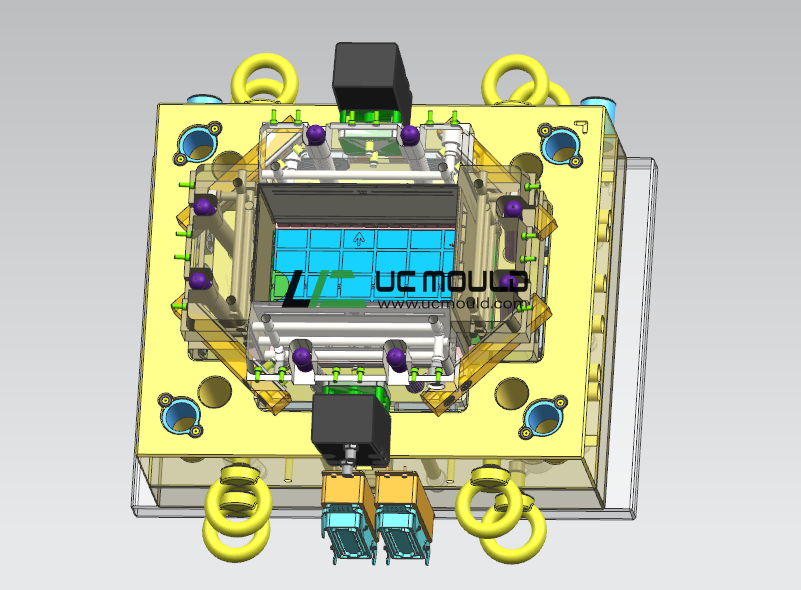

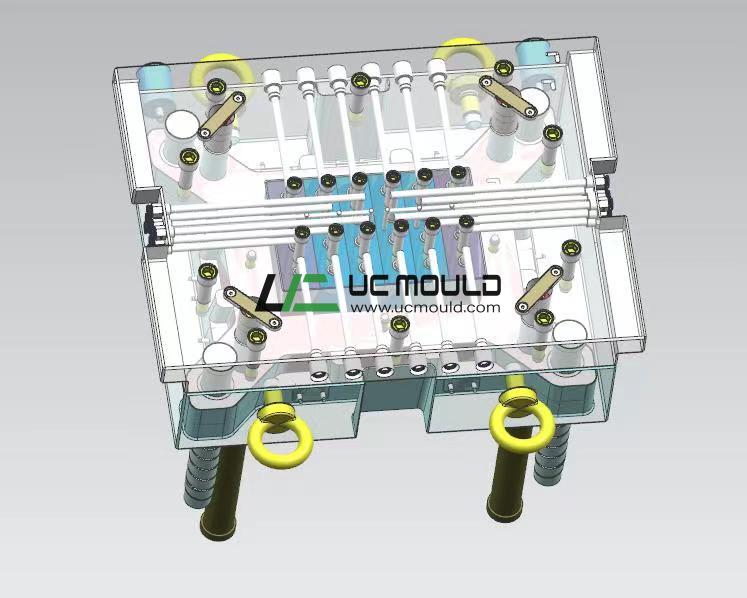

1. good cooling deisgn

2. hot runner injection gate location ,

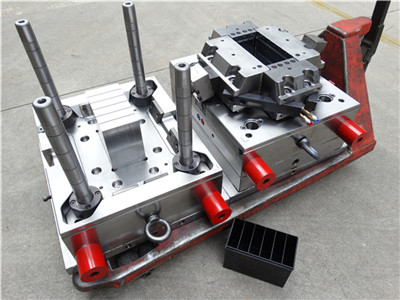

3. mould structure, the bottom of battery box mould should be inserted , like the mould photoes we showed. it help easier injeciton and easier mould maitainence. this is really really important .

4. good machining works, use high speed CNC machining to ensure the high precise.

4.good steel, the core side of battery box mould steel is H13 HRC43-45, the cavity side of battery box mould steel is 718HRC33-35. the core inserts hardness should be good enough, so that during injeciton the battery box each ribs can get precise wall thickness.